Hand-Soldering Surface Mount parts:

If you have never soldered surface mount before, I'll offer a few tips. Use a smaller soldering iron. The big trigger guns are out of the question. If you can afford it, a temperature controlled iron is your best bet. That doesn't just mean it has a knob (mine doesn't) but that it has a thermostat in the tip, and it will maintain the same temperature regardless of load (or a cool breeze coming by). I use an old Weller WTCPT series. There are other good brands as well. If you are shopping for one, ask around the forums, I'm sure you'll hear a few good suggestions. Of course, your iron should have a grounded tip, too.

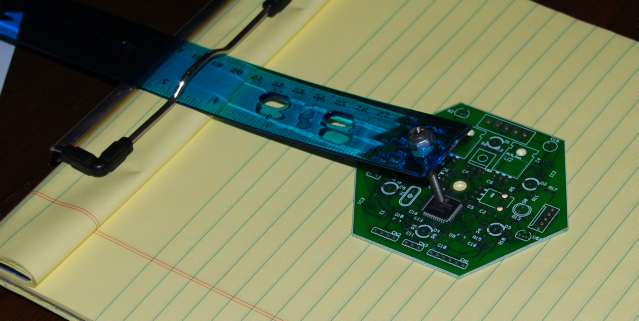

Soldering surface mount parts: There are many ways, from “wave” soldering to mask soldering, to baking them in a converted toaster oven. The biggest problem I had when hand soldering was keeping the chip in place. I could get it located perfectly, but as soon as I touch it with the tip of the iron, it would stick to the iron and all was lost. I fixed this with a simple tool anyone can make with stuff that is laying around the house. Take a ruler, or anything that resembles one, and add a small hole in one end if it's not there already. Then add a screw and a nut through the end. Find a clipboard, and use this under the clip to hold parts in place. Here's a quick picture, though I would prefer a wooden ruler.

That chip will stay put easily while soldering, and the ruler puts only a LIGHT pressure on the chip, so nothing gets damaged. No, that's not a MBMixer board, those have not arrived yet. (But it is a PIC18F458, alternate core, anyone?)

Once the chip is held down, just rest the tip of your iron so that it touches the end of each leg and the circuit board at the same time. Just a touch of solder and it should flow between the leg and board. Don't hold the iron there too long, chips can be damaged by too much heat.

After all the legs are soldered, inspect closely, looking for solder bridges. If you see one, lay a fresh bit of solder wick on top of the bridge, and lay the tip of your iron on top of that. The wick will get hot first, then melt the bridge, sucking the excess solder into the wick. This only works with fresh solder wick. Old stuff is worthless.