This is an old revision of the document!

Table of Contents

'ELO

Illuminated encoders and OLEDs mounted at 45 degrees. Optional touch sensors.

Schematic

WS2812 LEDs are arranged in a snake pattern entering at J1 and exiting at J2. R1 should be installed as a resistor 220-470R for the first module only and as a wire link for any subsequent WS2812 modules. There are pads for RC termination, which shouldn't be required.

A DIN chain scans the encoders and touch sensors coming in on J3 and out on J4. The encoders are assigned in columns to a 165 shift register with the top position using D0/D1, the second D1/D2, etc. Note that the clear-shaft encoders have the pin directions swapped; this should be taken into account in an MB_NG file. In theory the SRIO chain could be extended from J4.

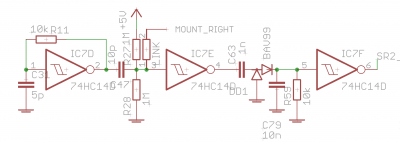

There are 16 separate touch sensor circuits as shown (circuit design adapted from Talking Electronics):

The first inverter comprises an oscillator feeding into another inverter. By touching the “LINK” part, the capacitance increases. The third inverter forms a comparator. In the normal state, the oscillator keeps the gate output low. When touched, the oscillator will “bleed” through and set the gate high. The actual part values may need adjusting to suit your own body/environment. To use plates mounted onto the encoder bodies, solder a wire link across the TS parts as noted. To use other metal pieces (e.g. an external keyboard), connect a wire to the pads adjacent to surface-mount parts.

- If touch sensors are not required, pins 9/10 of IC2 and IC5 can be bridged and the 165 chips/resistor networks omitted (this will obviously change the addressing of encoders!).

- If the 165 chips are installed but no touch sensors are used, then the resistor networks must also be installed.

- If touch sensors are used, then RN2/5 should be omitted. The inverter gates ensure a defined logic level.

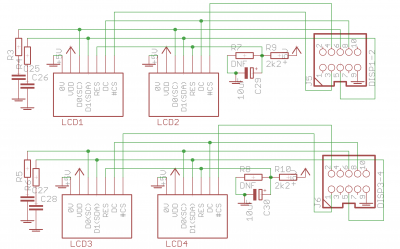

The OLED displays are connected as follows:

The reset circuits R9/R10/C29/C30 should be installed. The termination circuits R3-6/C25-28 shouldn't be required. When wiring ribbon cables, the end attached to the ELO board should have two IDCs on it; there is no connection on the PCB for the clock/data etc. lines between the two pairs of displays.

+5V Power enters through J7 and D1. There is no connection to +5V on other headers, apart from J4 to potentially drive SRIO modules.

BOM v1.0

Versions

v1.0: first release.

Assembly

Decide on the layout. Only four encoders are supported. ENSW1 and ENSW4 are always available; EN2/ENSW2 and EN3/ENSW3 share pins. The switch for ENSW2/ENSW3 is also shared. This way one can choose whether to have switched encoders or encoders illuminated with WS2812B LEDs.

If illuminated encoders are desired, install these and the associated capacitors first.

Next diodes and resistors/links. Align the diode band with the silkscreen legend. Next the two electrolytic caps.

OLEDs could be socketed using a right-angle pin header. This means a corresponding female header would need to replace the standard 7-pin one common to these displays.

Headers, switches and encoders come last. Note the flat part of the switch, which must align with the DT6 switch body. Illuminated encoders should be raised up around 2mm to fit over the LED and still turn freely.

Interconnection to Core

Headers are mentioned above. DIN/DOUT connect to DINX4/DOUTX4 or a DIOMATRIX. J10B to J10B

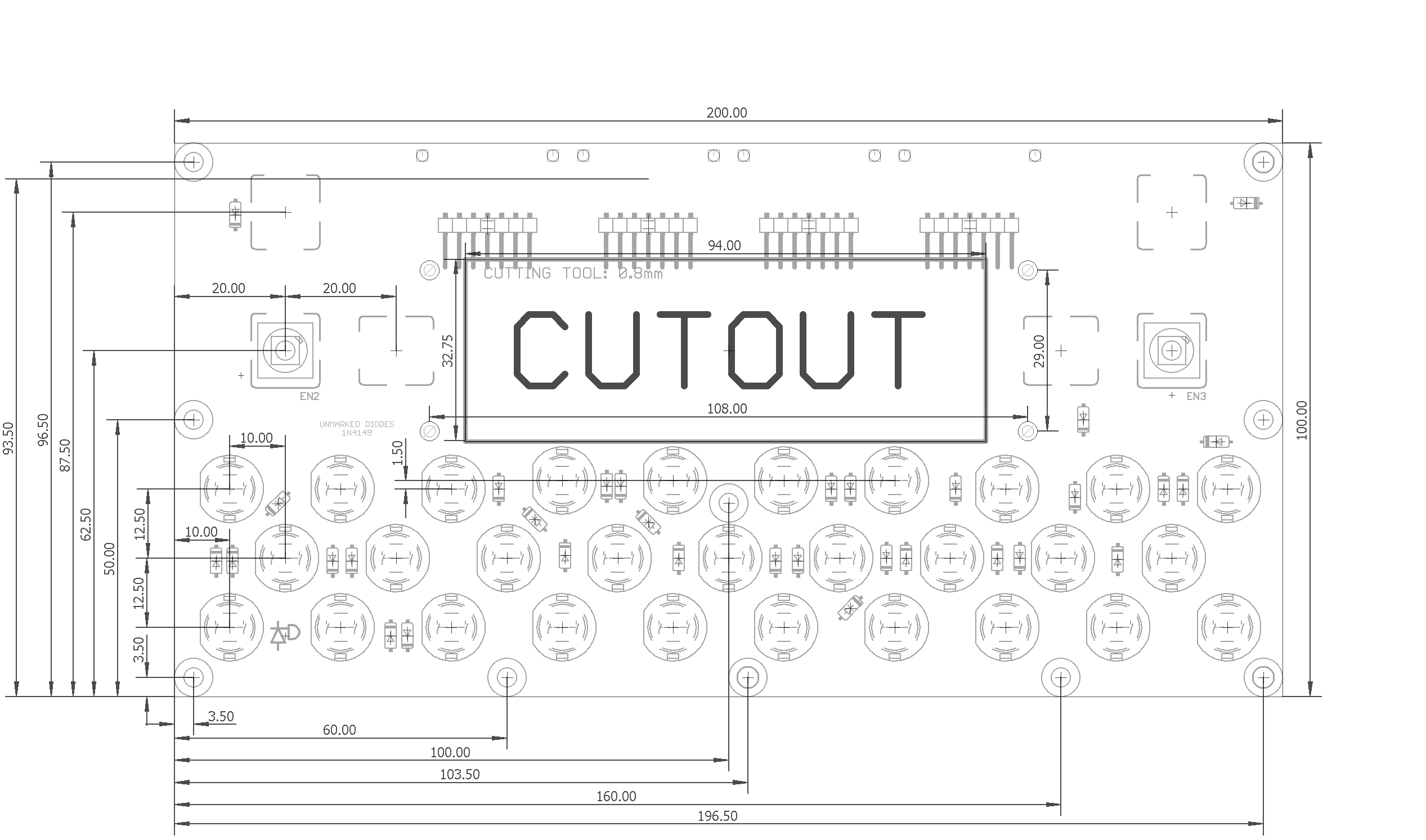

Dimensions

License

Currently the design is © 2018 antilog devices with all rights reserved; all documentation is CC BY-NC-SA 3.0.