This is an old revision of the document!

Table of Contents

MIDIbox Quad Genesis: Front Panel

To build the front panel of MIDIbox Quad Genesis, you will need (details on each part below):

- An aluminum front panel

- A PCB to hold all the buttons, LEDs, encoders, etc., and of course all these electronic components themselves

- A bunch of 3D printed transparent button caps

- Some 3D printed transparent LED pipes for the FM widget

- A 2×40 standard MIDIbox-compliant character LCD screen

- Knob caps for the encoders, including a datawheel-style cap for the datawheel encoder

- The dual-gang and single-gang potentiometers (one each per synth, not per module!) for the Genesis module volume controls, and their appropriate knob caps (see MBHP_GENESIS)

- A whole bunch of M3 or 4-40 screws, nuts, washers, and standoffs

- Standard MIDIbox 10-pin and 16-pin IDC cables, for connecting the front panel PCB to the core's J8/9 and for connecting the LCD to the core's J15A

Dimensions

The aluminum (or acrylic) front panel of MIDIbox Quad Genesis is 15“ x 11” (38.1 x 27.9 cm), and the front panel PCB itself is 13.85“ x 9.85” (35.18 x 25.02 cm), leaving a 0.57“ (1.45 cm) border around the edge. The aluminum I used was 1/16” (0.062“ or 1.57 mm); this may be a consideration if you use acrylic which is much thicker (2mm should probably be fine but 3mm might be a problem, with the 3D printed buttons - Update - Smithy has provided modified files for 3D printed buttons and light pipes to fit 3mm panels below. ).

The spacing between the underside of the front panel and the upper side of the PCB is about 0.27” (7 mm), which is originally defined by the encoders and the 3D printed buttons are made to match this. I used 1/4“ nylon spacers/standoffs from eBay plus a flat washer (4-40 or M3) to achieve this spacing. I used 0.75” 4-40 screws to put together the front panel, in which case the depth of the assembly was 0.75“ with the electrolytic capacitors and pin header / IDC connector sticking out past this. The panel and PCB can be fastened together with 4-40 or M3 screws.

Aluminum Front Panel

There are two designs available here: my original, and a modified design with the LED pipes in the LED rings having been replaced by 3mm LEDs just sticking through holes in the aluminum.

It took me over 2 hours just to insert the tiny LED pipes in the slits in one single front panel with the first design, which is why I recommend the second. Since they're 3D printed (see below), they have a small range of sizes, and at that scale some are too big and some are too small. I still left them in place for the FM widget and the DAC VU meter; if you don't want those either for some reason, it shouldn't be hard to replace them with holes.

All the LED holes and screw mounting holes are 1/8” (3.17 mm), which should give 3mm LEDs a little play (some are in practice slightly wider than 3mm, and some aren't actually 3mm at all), and are also big enough for both M3 and 4-40“ screws. On my own panel, I had to drill out some of the holes a bit for the yellow and green LEDs sticking through the front panel; I recommend you buy the LEDs you're going to put through the holes first and measure them before you have the front panel manufactured.

It may be possible to make the front panel out of acrylic, a-la MIDIbox SEQ V4. Since the front panel PCB is bolted to it in many places, it will probably be sturdy enough. If it's not, there's a row of screw holes slightly below halfway down the panel, and maybe you can have those screws go into an aluminum bar spanning the width of the front panel and attaching to the sides of your case, to provide extra support in the middle.

Downloads

(You will need to be logged in to your MIDIbox Forum account to access these downloads)

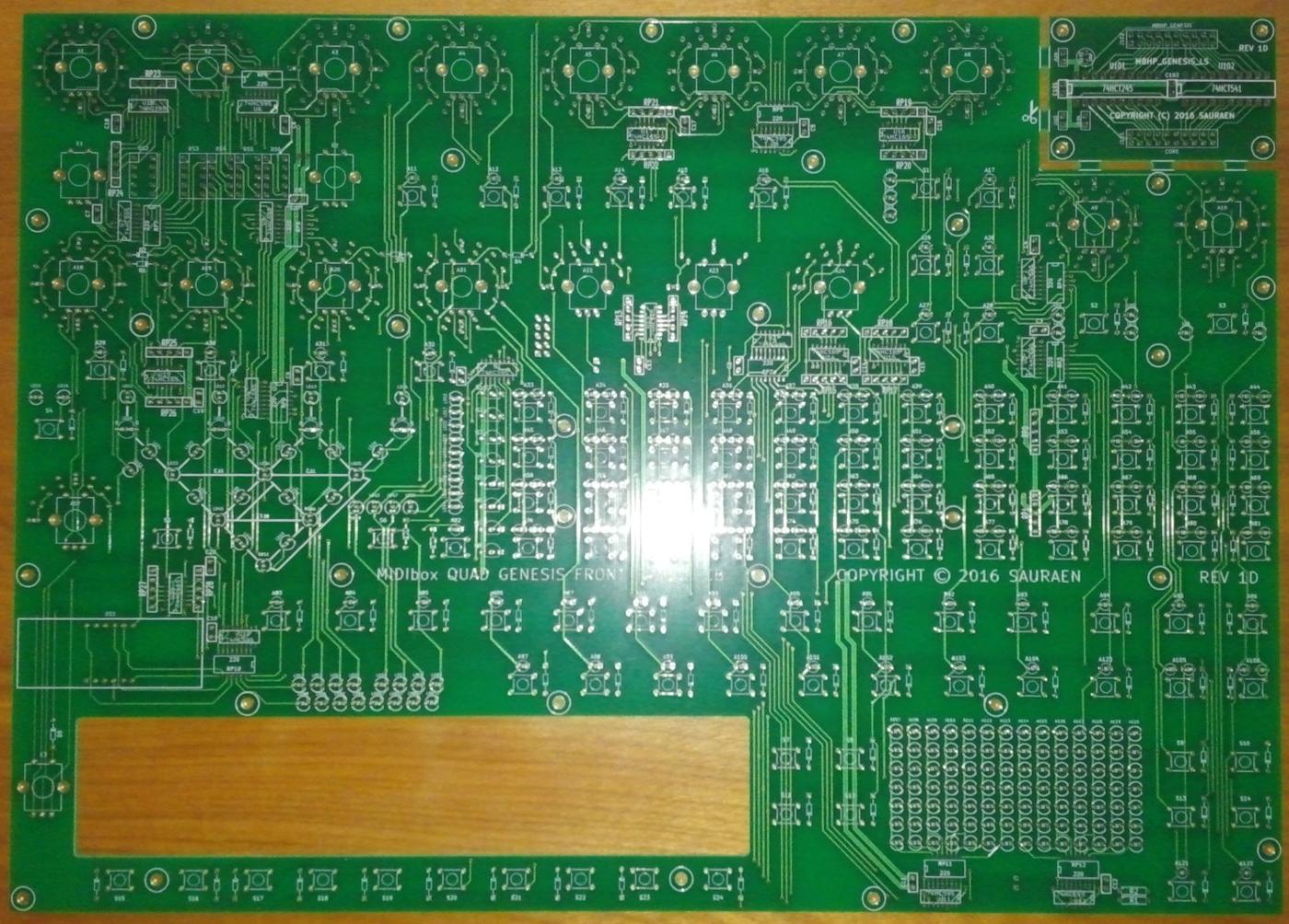

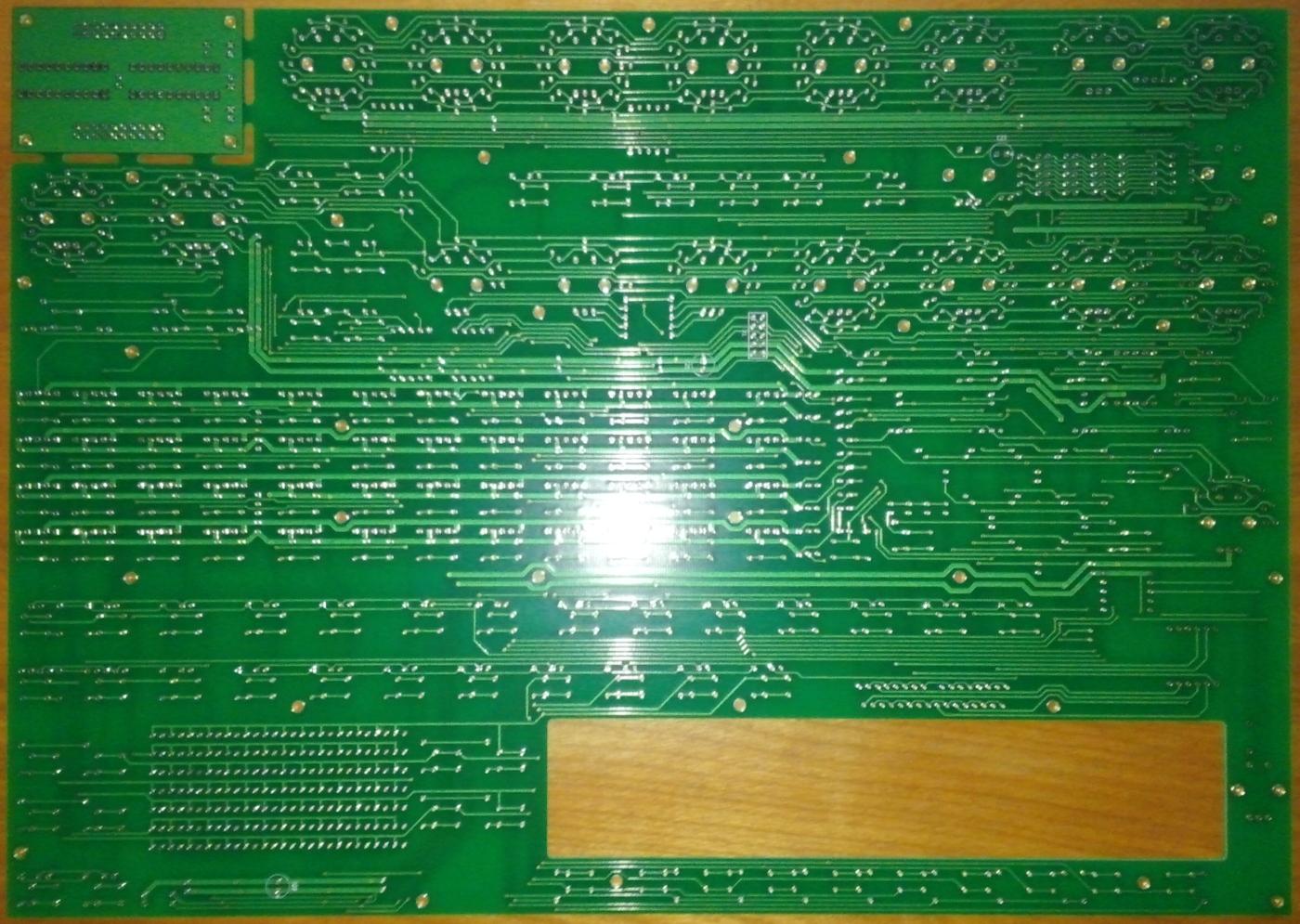

MBQG_FP PCB

A custom front panel PCB is purchaseable directly from Sauraen for $50 plus at-cost shipping. It includes a free detachable MBHP_GENESIS_LS PCB in the space where the volume knobs will be on the front panel. If you are interested in purchasing one, contact Sauraen by private message at the MIDIbox Forums or post in the MIDIbox Quad Genesis thread there.

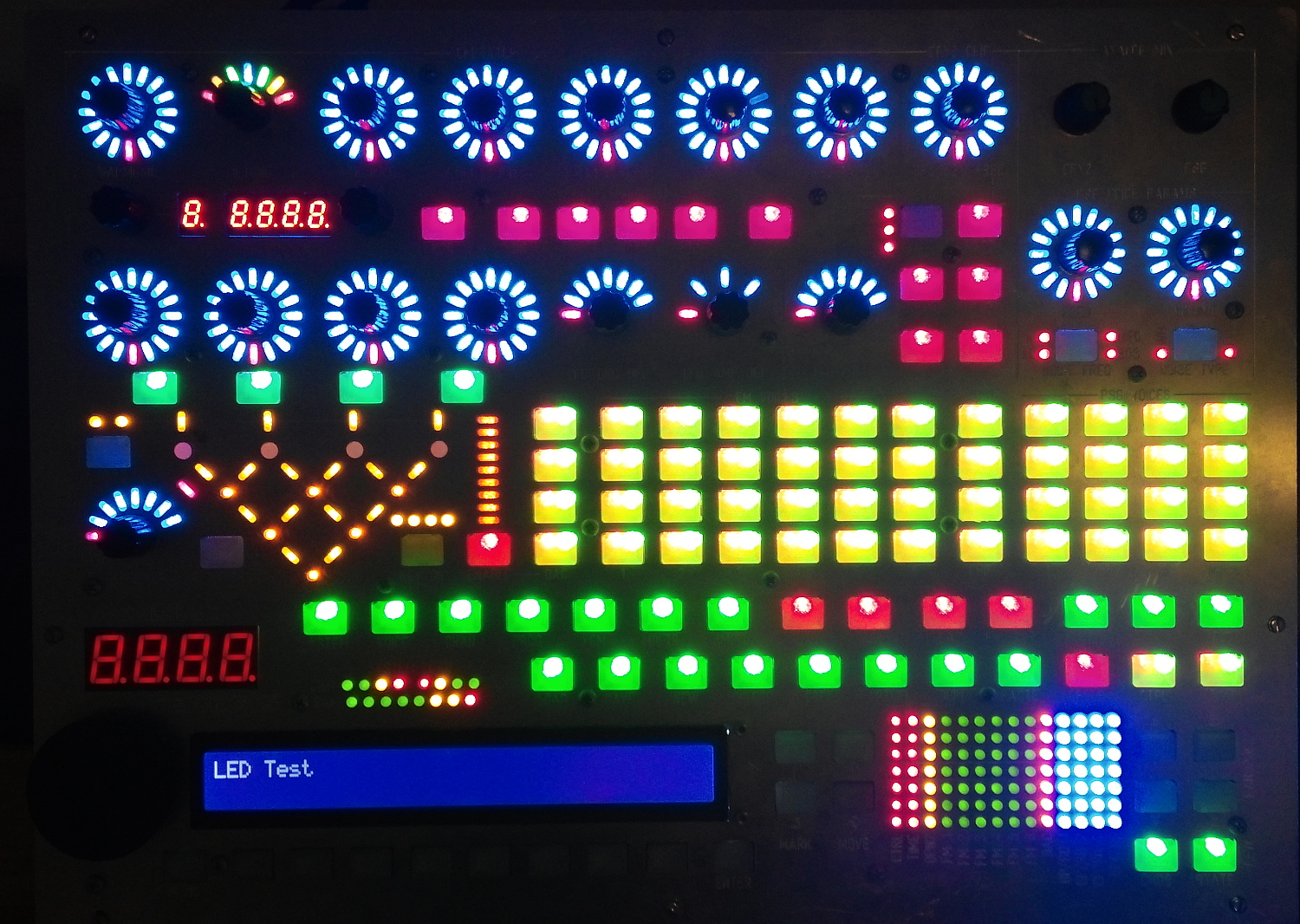

Photos

Parts List for MBQG_FP PCB

This is the set of parts I used to build the two MIDIbox Quad Genesis units I constructed. It can also serve as guidelines for if you're building your own board from scratch on veroboard. Here are some notes and caveats:

- As explained above in the section of the aluminum front panel, I used LED pipes for the LED rings, to give them a distinctive oblong shape. To save money on the milling costs and labor on inserting hundreds of tiny plastic pieces into the front panel, most of which are either too small or too big, I recommend making the LED rings just by having 3mm LEDs sticking up through the aluminum. In this case, the LEDs I used below will be too bright to look at directly–they were used to illuminate the LED pipes. So please consider changing to different LEDs.

- Please note that for the LEDs which are under illuminated buttons or under the remaining LED pipes, you will need LEDs which are very bright like the ones below! Cheap 1mcd LEDs will be completely invisible! You need at least 1000mcd; the brightnesses I used are listed below. If you are going to the trouble of making this thing, don't skimp on the LEDs!

- Also don't skimp on the encoders! For MIDIbox FM V2.0/V2.1 I used cheap encoders from China to save money, and many of them barely work anymore!

- Of course, the color of all the LEDs is completely up to personal preference, though you should always use the same two colors beneath all bi-color buttons. Please plan out carefully how many of each type of LED you will need based on your color preferences and which LEDs will be sticking through the front panel versus lighting up buttons or light pipes. Trust me, you don't want to use regular LEDs to try to light up the plastic, it'll look dim and poor; and you don't want to use the high-brightness LEDs sticking through the front panel, they will blind you!

- On the PCB itself, the individual buttons, LEDs, and diodes are usually not marked. To simplify PCB design in KiCad, “assemblies” were created with e.g. an encoder and 16 LEDs, or a button, two LEDs, and a diode. This is why they're marked “A21” or whatever. All the diodes are the same 1N914 or 1N4148 (or actually any through-hole small signal diode), and each one has a cathode marking, so there should never be any confusion. With the exception of the LEDs in the LED rings, every LED on the board has an actual diode symbol marked, so there should be no confusion about which direction they go (square pad is anode is longer lead). In the LED rings, the four quadrant LEDs' directions are marked, and the rest go in the corresponding direction, following around the circle (anode always on inside). All the tact switches are also the same–just make sure each one is pushed in fully before soldering!

| Description | Mouser P/N | Quantity |

|---|---|---|

| Encoders; 0.1” board mount with switch; bushing; 24 PPR, 24 detent; etc. If you want to save a couple dollars, you can use the ones without the switch for all the encoders except the datawheel and the four Operator Level encoders–those are the only ones for which the switch is wired up. | 652-PEC12R3220FS0024 | 21 |

| Tact switches; standard, 5mm high | 611-PTS645SM502 | 115 |

| Diodes for button matrix | 583-1N4148-T | 120 |

| Red LEDs for lighting buttons/caps (4500mcd (!)) | 604-WP710A10SRC/J4 | 87 |

| Orange LEDs for lighting buttons/caps (2700mcd (!)) | 604-WP710A10SEC | 9 |

| Yellow LEDs for lighting buttons/caps (3200mcd (!)) | 859-LTL17KYV3JS | 18 |

| Green LEDs for lighting buttons/caps (7200mcd (!)) | 859-LTL17KTGX3KS | 76 |

| Blue LEDs for lighting buttons/caps (1500mcd (!)) | 859-LTL17KTBS3KS | 220 |

| Red LEDs for panel indication (i.e. sticking through holes in front panel) (Tinted, Diffused) | 604-WP710A10SRD/D | 26 |

| Orange LEDs for panel indication (Tinted, Diffused) | 696-SSL-LX3044SOD | 7 |

| Yellow LEDs for panel indication (Tinted, Diffused) (For some reason I ended up using these only for the yellow LEDs in the commands display and the load meter, not for the crosspoints in the FM widget; it may have been because I wanted clear-looking LEDs in the FM widget to go with all the other clear/white things there, or because these LEDs are closer to yellow than to amber, and the other LEDs in the FM widget were more amber) | 710-151031YS06000 | 23 |

| Green LEDs for panel indication (Tinted, Clear–I couldn't get appropriate brightness diffused ones) | 859-LTL1CHJGTNN | 51 |

| Blue LEDs for panel indication (NOT tinted, Diffused–the picture lies, they're white diffused but light up blue; and actually these are a bit too bright to use for sticking through the front panel. You could fudge something with the resistors supplying these columns to try to reduce the brightness, but I might recommend looking for alternative LEDs.) | 593-VAOL-3LSBY1 | 28 |

| Red/Green 5mm LEDs for FM widget operator nodes (3 wire common ANODE) | 696-LLX5099SRSGCCA | 4 |

| Large LED display | 859-LTC-5623HR | 1 |

| Small LED displays | 859-LSHD-7501 | 5 |

| Row drive NMOSFETs (2n7000s aren't strong enough) | 689-VN3205N3-G | 8 |

| 74HC595 shift registers, SOIC-16 | 511-M74HC595YRM13TR | 12 |

| 74HC165 shift registers, SOIC-16 | 863-MC74HC165ADR2G | 8 |

| 220 ohm x 8 resistor packs, SOIC-16 | 652-4816P-1LF-220 | 11 |

| 10k ohm x 4 resistor packs, SIL-5 (RP13–RP28, not RP0 and RP1) | 858-L051S103LF | 16 |

| 1k ohm x 4 resistor packs, SIL-5 (these are just RP0 and RP1) | 652-4605X-1LF-1K | 2 |

| Electrolytic caps (470 uF) | 647-UVR1C471MPD | 3 |

| Ceramic/film caps (0.1 uF) | Buy by the 100 from eBay | ~20 |

| 10k dual gang audio taper panel mount pot (OPN2 volume) | 313-1240F-10K | 1 |

| 10k audio taper panel mount pot | 858-P160KNPC15A10K | 1 |

| 5×2 pin header | Buy in larger size (preferably from eBay) and snap off | 1 |

Don't forget: the 2×40 character LCD, the pin header for the LCD, the ribbon cable and IDC connectors for the LCD and front panel, knob caps for the regular encoders, datawheel knob cap for the datawheel, knob caps for the volume pots.

Schematic and Reference Designators

Schematic image (unfortunately, MIDIbox Gallery scaled down the original image, and offsite documentation is frowned upon):

For Color fields, as discussed above, you may change the colors to whatever you want, but it is recommended to keep the colors consistent (e.g. make everything “green” below be the same color, and everything “red” below be a different color). For the Red/Green buttons below, the Red LED is always on the left and the Green LED is always on the right.

| Ref. Des. | Type | Color | Description |

|---|---|---|---|

| A1 | Encoder + 16-LED ring | Blue | FM operator parameter “Harmonic” (“FMult”) |

| A2 | Encoder + 7-LED ring | Rainbow | FM operator parameter “Detune” |

| A3 | Encoder + 16-LED ring | Blue | FM operator parameter “Atk Rate” |

| A4 | Encoder + 16-LED ring | Blue | FM operator parameter “Dec1 Rate” |

| A5 | Encoder + 16-LED ring | Blue | FM operator parameter “Dec1 Level” |

| A6 | Encoder + 16-LED ring | Blue | FM operator parameter “Dec2 Rate” |

| A7 | Encoder + 16-LED ring | Blue | FM operator parameter “Rel Rate” |

| A8 | Encoder + 16-LED ring | Blue | OPN2 parameter “Ch3 CSM Freq” |

| A9 | Encoder + 16-LED ring | Blue | PSG voice parameter “Freq” |

| A10 | Encoder + 16-LED ring | Blue | PSG voice parameter “Volume” |

| A11 | Button + LED | Red | FM operator parameter “KSR” (Key Scale Rate) |

| A12 | Button + LED | Red | FM operator SSG-EG parameter “On” |

| A13 | Button + LED | Red | FM operator SSG-EG parameter “Init” |

| A14 | Button + LED | Red | FM operator SSG-EG parameter “Toggle” |

| A15 | Button + LED | Red | FM operator SSG-EG parameter “Hold” |

| A16 | Button + LED | Red | FM operator parameter “LFO AM” (LFO → operator amplitude modulation toggle) |

| A17 | Button + LED | Red | OPN2 parameter “Ch3 CSM Fast” (originally Timer A fast, now Timer A enable) |

| A18–A21 | Encoder + 16-LED ring | Blue | FM voice parameter “Oper 1 Level” – “Oper 4 Level” |

| A22 | Encoder + 8-LED ring | Blue | FM voice parameter “LFO-Freq Depth” (LFO → frequency modulation depth) |

| A23 | Encoder + 4-LED ring | Blue | FM voice parameter “LFO-Amp Depth” (LFO → amplitude modulation depth) |

| A24 | Encoder + 8-LED ring | Blue | OPN2 parameter “LFO Freq” |

| A25 | Button + LED | Red | OPN2 parameter “Ugly” (now-famous test bit 0x21:4) |

| A26 | Button + LED | Red | OPN2 parameter “DAC Override” (test bit 0x2C:5) |

| A27 | Button + LED | Red | OPN2 parameter “LFO Enable” |

| A28 | Button + LED | Red | OPN2 parameter “EG Enable” (invert of test bit 0x21:5) |

| A29–A32 | Button + LED | Green | Operator Selection 1–4 |

| A33–A44 | Button + 2 LEDs | Red/Green | Genesis 1 Voice Selection: DAC, FM voices 1–6, OPN2 globals, PSG voices 1-3, noise |

| A45–A56 | Button + 2 LEDs | Red/Green | Genesis 2 Voice Selection: DAC, FM voices 1–6, OPN2 globals, PSG voices 1-3, noise |

| A57 | Encoder + 8-LED ring | Blue | OPN2 voice parameter “Feedback” |

| A58–A69 | Button + 2 LEDs | Red/Green | Genesis 3 Voice Selection: DAC, FM voices 1–6, OPN2 globals, PSG voices 1-3, noise |

| A70–A81 | Button + 2 LEDs | Red/Green | Genesis 4 Voice Selection: DAC, FM voices 1–6, OPN2 globals, PSG voices 1-3, noise |

| A82 | Button + LED | Red | OPN2 parameter “DAC Enable” |

| A83 | Button + LED | Green | System Mode |

| A84 | Button + LED | Green | Voice Mode |

| A85 | Button + LED | Green | Channel Mode |

| A86 | Button + LED | Green | Program Mode |

| A87 | Button + LED | Green | VGM Editor Mode |

| A88 | Button + LED | Green | Modulator Mode |

| A89 | Button + LED | Green | Sample Mode |

| A90 | Button + LED | Red | Mute |

| A91 | Button + LED | Red | Solo |

| A92 | Button + LED | Red | Release |

| A93 | Button + LED | Red | Panel Override |

| A94 | Button + LED | Green | Restart |

| A95 | Button + LED | Green | Play |

| A96 | Button + LED | Green | Reset |

| A97 | Button + LED | Green | Load |

| A98 | Button + LED | Green | Save |

| A99 | Button + LED | Green | New |

| A100 | Button + LED | Green | Delete |

| A101 | Button + LED | Green | Crop |

| A102 | Button + LED | Green | Capture |

| A103 | Button + LED | Green | Duplicate |

| A104 | Button + LED | Green | Paste |

| A105 | Button + LED | Red/Green | Ctrl |

| A106 | Button + LED | Red/Green | Time |

| A107 | 7-LED Column | Red | VGM Commands Display: Ctrl |

| A108 | 7-LED Column | Red | VGM Commands Display: Time |

| A109 | 7-LED Column | Yellow | VGM Commands Display: OPN2 |

| A110 | 7-LED Column | Green | VGM Commands Display: FM 1 |

| A111 | 7-LED Column | Green | VGM Commands Display: FM 2 |

| A112 | 7-LED Column | Green | VGM Commands Display: FM 3 |

| A113 | 7-LED Column | Green | VGM Commands Display: FM 4 |

| A114 | 7-LED Column | Green | VGM Commands Display: FM 5 |

| A115 | 7-LED Column | Green | VGM Commands Display: FM 6 |

| A116 | 7-LED Column | Orange | VGM Commands Display: DAC |

| A117 | 7-LED Column | Blue | VGM Commands Display: OP/SQ 1 |

| A118 | 7-LED Column | Blue | VGM Commands Display: OP/SQ 2 |

| A119 | 7-LED Column | Blue | VGM Commands Display: OP/SQ 3 |

| A120 | 7-LED Column | Blue | VGM Commands Display: OP4/NS |

| A121 | Button + LED | Green | Commands View |

| A122 | Button + LED | Green | State View |

| A123 | Button + LED | Red | Group |

| C1–C20 | Capacitor | N/A | 0.1uF ceramic or film capacitors for chips |

| C21–C23 | Capacitor | N/A | 470uF electrolytic capacitors for power rails, reverse mounted |

| D1–D5 | Diode | N/A | Diodes for encoder buttons; all normal button diodes included in Assembly or Switch |

| DS1 | LED Display | Red | Main Display |

| DS2 | LED Display | Red | Octave |

| DS3–DS6 | LED Display | Red | Frequency |

| E1 | Encoder | N/A | OPN2 voice parameter “Octave” |

| E2 | Encoder | N/A | OPN2 voice parameter “Frequency” |

| E3 | Encoder | N/A | Datawheel |

| LD1–LD3 | LED | Red | OPN2 Ch3 Mode |

| LD4–LD7 | LED | Red | PSG Noise Freq |

| LD8–LD9 | LED | Red | PSG Noise Type |

| LD10, LD16 | LED | Yellow | FM Voice Output |

| LD11–LD14, LD24–LD29, LD37–LD40, LD48–LD49 | LED | Yellow | FM Widget Path |

| LD15, LD17, LD22, LD23, LD30, LD31, LD36, LD42, LD44 | LED | Orange | DAC VU Meter |

| LD18–LD21 | Bicolor LED | Red/Green | FM Widget Operator Node |

| LD33–LD35, LD45–LD46, LD51 | LED | Yellow | FM Widget Path Node |

| LD32 | LED | Red | FM Widget Feedback |

| LD41, LD43, LD47, LD50 | LED | Yellow | Key On |

| LD52–LD53, LD58-LD59, LD60-LD64, | LED | Green | System Load Meter |

| LD54, LD57, LD65-LD66, | LED | Yellow | System Load Meter |

| LD55-LD56, LD67 | LED | Red | System Load Meter |

| R1–R2 | Resistors | N/A | 2.2k terminating resistors for clock and latch lines |

| RP0–RP1 | Resistor Packs | N/A | 1k row driver pull-ups (to reduce ghosting) |

| RP2–RP12 | Resistor Packs | N/A | 220 ohm LED column current limiters |

| RP13–RP28 | Resistor Packs | N/A | 10k button column pull-ups |

| S1 | Button | N/A | OPN2 Ch3 Mode |

| S2 | Button | N/A | PSG Noise Freq |

| S3 | Button | N/A | PSG Noise Type |

| S4 | Button | N/A | FM Voice Output |

| S5 | Button | N/A | Algorithm |

| S6 | Button | N/A | Key On |

| S7 | Button | N/A | Mark Beginning |

| S8 | Button | N/A | Move Up |

| S9 | Button | N/A | Up One Command |

| S10 | Button | N/A | Up One State |

| S11 | Button | N/A | Mark End |

| S12 | Button | N/A | Move Down |

| S13 | Button | N/A | Down One Command |

| S14 | Button | N/A | Down One State |

| S15 | Button | N/A | Menu |

| S16–S23 | Button | N/A | Softkeys |

| S24 | Button | N/A | Enter |

| TF1 | Triforce | Red | Triforce of Power |

| TF2 | Triforce | Blue | Triforce of Wisdom |

| TF3 | Triforce | Green | Triforce of Courage |

| U1–U12 | IC | N/A | 74HC595 Output Shift Register, SMD |

| U13–U20 | IC | N/A | 74HC165 Input Shift Register, SMD |

Custom PCB / Veroboard Info

This is the mapping for the MBQG_FP board itself–if you have the commercially produced PCB from Sauraen, you don't need this info because it's already in the copper!

MIDIbox Quad Genesis supports its front panel controls in any valid MIDIbox button-LED matrix configuration, with the following restrictions:

DOUT Restrictions

- The same BLM must be used for buttons and LEDs, and it must have 8 rows.

- LED display digits must be common anode, connected with their anode to a DOUT shift register pin, and their cathodes to the row lines in the order 0-7 = A-B-C-D-E-F-G-DP.

DIN Restrictions

- The same BLM must be used for buttons and LEDs, and it must have 8 rows.

- Encoders must have their common pin grounded, and their two switching pins directly connected to two DIN shift register pins (not in the matrix).

For now, the mapping is hard-coded in frontpanel.c, but eventually (if there is interest), it will be read from a text-based configuration file on the SD card upon startup. If you match the matrix maps below, you won't need to edit this at all.

DOUT Matrix Map

Syntax:

- X = no item

- B = button

- EB = encoder button (push)

- L = LED

- R = Red

- G = Green

- G# = Genesis #

- O# = LED Ring Segment # (counted from bottom, clockwise)

- LW# = LED, FM Widget, Reference Designator # (since there is no good way to label the individual widget segments)

All LED display digits are wired, from rows 0 to 7: A-B-C-D-E-F-G-DP

VGM Commands Matrix is wired, from top to bottom, 0-1-2-3-4-5-6 (row 7 not used for any columns)

Counting the individual segments in the LED displays, there are 638 LEDs on the front panel.

| SR | IDX | BIT | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

|---|---|---|---|---|---|---|---|---|---|---|

| U1 | 1 | 0 | ROW0 DRIVER (ACTIVE HIGH) | |||||||

| 1 | ROW1 DRIVER (ACTIVE HIGH) | |||||||||

| 2 | ROW2 DRIVER (ACTIVE HIGH) | |||||||||

| 3 | ROW3 DRIVER (ACTIVE HIGH) | |||||||||

| 4 | ROW4 DRIVER (ACTIVE HIGH) | |||||||||

| 5 | ROW5 DRIVER (ACTIVE HIGH) | |||||||||

| 6 | ROW6 DRIVER (ACTIVE HIGH) | |||||||||

| 7 | ROW7 DRIVER (ACTIVE HIGH) | |||||||||

| U2 | 2 | 0 | LR_G1_DAC | LG_G1_DAC | LR_G2_DAC | LG_G2_DAC | LR_G3_DAC | LG_G3_DAC | LR_G4_DAC | LG_G4_DAC |

| 1 | LR_G1_V1 | LG_G1_V1 | LR_G2_V1 | LG_G2_V1 | LR_G3_V1 | LG_G3_V1 | LR_G4_V1 | LG_G4_V1 | ||

| 2 | LR_G1_V2 | LG_G1_V2 | LR_G2_V2 | LG_G2_V2 | LR_G3_V2 | LG_G3_V2 | LR_G4_V2 | LG_G4_V2 | ||

| 3 | LR_G1_V3 | LG_G1_V3 | LR_G2_V3 | LG_G2_V3 | LR_G3_V3 | LG_G3_V3 | LR_G4_V3 | LG_G4_V3 | ||

| 4 | LR_G1_V4 | LG_G1_V4 | LR_G2_V4 | LG_G2_V4 | LR_G3_V4 | LG_G3_V4 | LR_G4_V4 | LG_G4_V4 | ||

| 5 | LR_G1_V5 | LG_G1_V5 | LR_G2_V5 | LG_G2_V5 | LR_G3_V5 | LG_G3_V5 | LR_G4_V5 | LG_G4_V5 | ||

| 6 | X | X | X | X | LFOFREQ_O4 | LFOFREQ_O5 | LFOFREQ_O6 | LFOFREQ_O7 | ||

| 7 | X | X | X | X | LFOFREQ_O11 | LFOFREQ_O10 | LFOFREQ_O9 | LFOFREQ_O8 | ||

| U3 | 3 | 0 | LR_G1_V6 | LG_G1_V6 | LR_G2_V6 | LG_G2_V6 | LR_G3_V6 | LG_G3_V6 | LR_G4_V6 | LG_G4_V6 |

| 1 | LR_G1_OPN2 | LG_G1_OPN2 | LR_G2_OPN2 | LG_G2_OPN2 | LR_G3_OPN2 | LG_G3_OPN2 | LR_G4_OPN2 | LG_G4_OPN2 | ||

| 2 | LG_CTRL | X | LR_CTRL | X | LG_TIME | L_CMDS | LR_TIME | L_STATE | ||

| 3 | L_GROUP | L_MUTE | L_RESTART | L_SOLO | L_PLAY | L_RELEASE | L_RESET | L_PNLOVR | ||

| 4 | LR_G1_S1 | LG_G1_S1 | LR_G2_S1 | LG_G2_S1 | LR_G3_S1 | LG_G3_S1 | LR_G4_S1 | LG_G4_S1 | ||

| 5 | LR_G1_S2 | LG_G1_S2 | LR_G2_S2 | LG_G2_S2 | LR_G3_S2 | LG_G3_S2 | LR_G4_S2 | LG_G4_S2 | ||

| 6 | LR_G1_S3 | LG_G1_S3 | LR_G2_S3 | LG_G2_S3 | LR_G3_S3 | LG_G3_S3 | LR_G4_S3 | LG_G4_S3 | ||

| 7 | LR_G1_NOISE | LG_G1_NOISE | LR_G2_NOISE | LG_G2_NOISE | LR_G3_NOISE | LG_G3_NOISE | LR_G4_NOISE | LG_G4_NOISE | ||

| U4 | 4 | 0 | X | X | X | X | X | L_CH3NORM | L_CH34FREQ | L_CH3CSM |

| 1 | X | X | L_EG | L_LFO | L_DACOVR | L_UGLY | L_CH3FAST | X | ||

| 2 | L_NFMED | L_NFHI | L_KSR | L_SSGON | L_SSGINIT | L_SSGTGL | L_SSGHOLD | L_LFOAM | ||

| 3 | L_NFSQ3 | L_NFLO | L_NMPLS | L_NMWHT | X | X | X | X | ||

| 4 | PSGVOL_O15 | PSGVOL_O14 | PSGVOL_O13 | PSGVOL_O12 | PSGVOL_O11 | PSGVOL_O10 | PSGVOL_O9 | PSGVOL_O8 | ||

| 5 | PSGVOL_O0 | PSGVOL_O1 | PSGVOL_O2 | PSGVOL_O3 | PSGVOL_O4 | PSGVOL_O5 | PSGVOL_O6 | PSGVOL_O7 | ||

| 6 | PSGFREQ_O15 | PSGFREQ_O14 | PSGFREQ_O13 | PSGFREQ_O12 | PSGFREQ_O11 | PSGFREQ_O10 | PSGFREQ_O9 | PSGFREQ_O8 | ||

| 7 | PSGFREQ_O0 | PSGFREQ_O1 | PSGFREQ_O2 | PSGFREQ_O3 | PSGFREQ_O4 | PSGFREQ_O5 | PSGFREQ_O6 | PSGFREQ_O7 | ||

| U5 | 5 | 0 | RELRATE_O15 | RELRATE_O14 | RELRATE_O13 | RELRATE_O12 | RELRATE_O11 | RELRATE_O10 | RELRATE_O9 | RELRATE_O8 |

| 1 | RELRATE_O0 | RELRATE_O1 | RELRATE_O2 | RELRATE_O3 | RELRATE_O4 | RELRATE_O5 | RELRATE_O6 | RELRATE_O7 | ||

| 2 | CSMFREQ_O15 | CSMFREQ_O14 | CSMFREQ_O13 | CSMFREQ_O12 | CSMFREQ_O11 | CSMFREQ_O10 | CSMFREQ_O9 | CSMFREQ_O8 | ||

| 3 | CSMFREQ_O0 | CSMFREQ_O1 | CSMFREQ_O2 | CSMFREQ_O3 | CSMFREQ_O4 | CSMFREQ_O5 | CSMFREQ_O6 | CSMFREQ_O7 | ||

| 4 | DECLVL_O15 | DECLVL_O14 | DECLVL_O13 | DECLVL_O12 | DECLVL_O11 | DECLVL_O10 | DECLVL_O9 | DECLVL_O8 | ||

| 5 | DECLVL_O0 | DECLVL_O1 | DECLVL_O2 | DECLVL_O3 | DECLVL_O4 | DECLVL_O5 | DECLVL_O6 | DECLVL_O7 | ||

| 6 | DEC2R_O15 | DEC2R_O14 | DEC2R_O13 | DEC2R_O12 | DEC2R_O11 | DEC2R_O10 | DEC2R_O9 | DEC2R_O8 | ||

| 7 | DEC2R_O0 | DEC2R_O1 | DEC2R_O2 | DEC2R_O3 | DEC2R_O4 | DEC2R_O5 | DEC2R_O6 | DEC2R_O7 | ||

| U6 | 6 | 0 | DEC1R_O15 | DEC1R_O14 | DEC1R_O13 | DEC1R_O12 | DEC1R_O11 | DEC1R_O10 | DEC1R_O9 | DEC1R_O8 |

| 1 | DEC1R_O0 | DEC1R_O1 | DEC1R_O2 | DEC1R_O3 | DEC1R_O4 | DEC1R_O5 | DEC1R_O6 | DEC1R_O7 | ||

| 2 | ATTACK_O15 | ATTACK_O14 | ATTACK_O13 | ATTACK_O12 | ATTACK_O11 | ATTACK_O10 | ATTACK_O9 | ATTACK_O8 | ||

| 3 | ATTACK_O0 | ATTACK_O1 | ATTACK_O2 | ATTACK_O3 | ATTACK_O4 | ATTACK_O5 | ATTACK_O6 | ATTACK_O7 | ||

| 4 | X | X | X | X | DETUNE_O11 | DETUNE_O10 | DETUNE_O9 | DETUNE_O8 | ||

| 5 | X | X | X | X | X | DETUNE_O5 | DETUNE_O6 | DETUNE_O7 | ||

| 6 | HARM_O15 | HARM_O14 | HARM_O13 | HARM_O12 | HARM_O11 | HARM_O10 | HARM_O9 | HARM_O8 | ||

| 7 | HARM_O0 | HARM_O1 | HARM_O2 | HARM_O3 | HARM_O4 | HARM_O5 | HARM_O6 | HARM_O7 | ||

| U7 | 7 | 0 | OP1LVL_O0 | OP1LVL_O1 | OP1LVL_O2 | OP1LVL_O3 | OP1LVL_O4 | OP1LVL_O5 | OP1LVL_O6 | OP1LVL_O7 |

| 1 | OP1LVL_O15 | OP1LVL_O14 | OP1LVL_O13 | OP1LVL_O12 | OP1LVL_O11 | OP1LVL_O10 | OP1LVL_O9 | OP1LVL_O8 | ||

| 2 | OP2LVL_O0 | OP2LVL_O1 | OP2LVL_O2 | OP2LVL_O3 | OP2LVL_O4 | OP2LVL_O5 | OP2LVL_O6 | OP2LVL_O7 | ||

| 3 | OP2LVL_O15 | OP2LVL_O14 | OP2LVL_O13 | OP2LVL_O12 | OP2LVL_O11 | OP2LVL_O10 | OP2LVL_O9 | OP2LVL_O8 | ||

| 4 | FREQUENCY DIGIT 3 COMMON ANODE | |||||||||

| 5 | FREQUENCY DIGIT 2 COMMON ANODE | |||||||||

| 6 | FREQUENCY DIGIT 1 COMMON ANODE | |||||||||

| 7 | OCTAVE DIGIT COMMON ANODE | |||||||||

| U8 | 8 | 0 | OP3LVL_O0 | OP3LVL_O1 | OP3LVL_O2 | OP3LVL_O3 | OP3LVL_O4 | OP3LVL_O5 | OP3LVL_O6 | OP3LVL_O7 |

| 1 | OP3LVL_O15 | OP3LVL_O14 | OP3LVL_O13 | OP3LVL_O12 | OP3LVL_O11 | OP3LVL_O10 | OP3LVL_O9 | OP3LVL_O8 | ||

| 2 | OP4LVL_O0 | OP4LVL_O1 | OP4LVL_O2 | OP4LVL_O3 | OP4LVL_O4 | OP4LVL_O5 | OP4LVL_O6 | OP4LVL_O7 | ||

| 3 | OP4LVL_O15 | OP4LVL_O14 | OP4LVL_O13 | OP4LVL_O12 | OP4LVL_O11 | OP4LVL_O10 | OP4LVL_O9 | OP4LVL_O8 | ||

| 4 | X | X | X | X | LFOFDEP_O4 | LFOFDEP_O5 | LFOFDEP_O6 | LFOFDEP_O7 | ||

| 5 | X | X | X | X | LFOFDEP_O11 | LFOFDEP_O10 | LFOFDEP_O9 | LFOFDEP_O8 | ||

| 6 | X | X | X | X | LFOADEP_O4 | LFOADEP_O10 | LFOADEP_O6 | LFOADEP_O8 | ||

| 7 | FREQUENCY DIGIT 4 COMMON ANODE | |||||||||

| U9 | 9 | 0 | X | X | X | X | L_DACB9 | L_DACENAB | LW46 | X |

| 1 | LW45 | LW48 | LW51 | LW49 | L_KON1 | L_KON2 | L_KON3 | L_KON4 | ||

| 2 | FEEDBACK_O11 | FEEDBACK_O10 | FEEDBACK_O9 | FEEDBACK_O8 | L_DACB5 | L_DACB6 | L_DACB7 | L_DACB8 | ||

| 3 | FEEDBACK_O4 | FEEDBACK_O5 | FEEDBACK_6 | FEEDBACK_7 | L_DACB1 | L_DACB2 | L_DACB3 | L_DACB4 | ||

| 4 | LW32 | LW33 | LW37 | LW38 | LW34 | LW39 | LW40 | LW35 | ||

| 5 | L_OUTL | L_OUTR | LW24 | LW25 | LW26 | LW27 | LW28 | LW29 | ||

| 6 | LR_OP1 | LG_OP1 | LR_OP2 | LG_OP2 | LR_OP3 | LG_OP3 | LR_OP4 | LG_OP4 | ||

| 7 | L_SELO1 | L_CARRO1 | L_SELO2 | L_CARRO2 | L_SELO3 | L_CARRO3 | L_SELO4 | L_CARRO4 | ||

| U10 | 10 | 0 | MAIN DIGIT 4 COMMON ANODE | |||||||

| 1 | MAIN DIGIT 3 COMMON ANODE | |||||||||

| 2 | MAIN DIGIT 2 COMMON ANODE | |||||||||

| 3 | MAIN DIGIT 1 COMMON ANODE | |||||||||

| 4 | L_RAM0 | L_RAM1 | L_RAM2 | L_RAM3 | L_RAM4 | L_RAM5 | L_RAM6 | L_RAM7 | ||

| 5 | L_CHIP0 | L_CHIP1 | L_CHIP2 | L_CHIP3 | L_CARD3 | L_CARD2 | L_CARD1 | L_CARD0 | ||

| 6 | L_LOAD | L_CROP | L_SAVE | L_CAPTURE | L_NEW | L_DUPL | L_DELETE | L_PASTE | ||

| 7 | L_PROG | X | L_VGM | L_SYSTEM | L_MDLTR | L_VOICE | L_SAMPLE | L_CHAN | ||

| U11 | 11 | 0 | VGM COMMANDS MATRIX COLUMN 7: FM 4 | |||||||

| 1 | VGM COMMANDS MATRIX COLUMN 6: FM 3 | |||||||||

| 2 | VGM COMMANDS MATRIX COLUMN 5: FM 2 | |||||||||

| 3 | VGM COMMANDS MATRIX COLUMN 4: FM 1 | |||||||||

| 4 | VGM COMMANDS MATRIX COLUMN 3: OPN2 | |||||||||

| 5 | VGM COMMANDS MATRIX COLUMN 2: TIME | |||||||||

| 6 | VGM COMMANDS MATRIX COLUMN 1: CTRL | |||||||||

| 7 | X | |||||||||

| U12 | 12 | 0 | X | |||||||

| 1 | VGM COMMANDS MATRIX COLUMN 14: OP4/NS | |||||||||

| 2 | VGM COMMANDS MATRIX COLUMN 13: OP/SQ 3 | |||||||||

| 3 | VGM COMMANDS MATRIX COLUMN 12: OP/SQ 2 | |||||||||

| 4 | VGM COMMANDS MATRIX COLUMN 11: OP/SQ 1 | |||||||||

| 5 | VGM COMMANDS MATRIX COLUMN 10: DAC | |||||||||

| 6 | VGM COMMANDS MATRIX COLUMN 9: FM 6 | |||||||||

| 7 | VGM COMMANDS MATRIX COLUMN 8: FM 5 | |||||||||

DIN Matrix Map

| SR | IDX | BIT | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

|---|---|---|---|---|---|---|---|---|---|---|

| U13 | 1 | 0 | OP4LVL ENCODER A | |||||||

| 1 | OP4LVL ENCODER B | |||||||||

| 2 | LFOFDEP ENCODER B | |||||||||

| 3 | LFOFDEP ENCODER A | |||||||||

| 4 | LFOADEP ENCODER B | |||||||||

| 5 | LFOADEP ENCODER A | |||||||||

| 6 | LFOFREQ ENCODER A | |||||||||

| 7 | LFOFREQ ENCODER B | |||||||||

| U14 | 2 | 0 | B_MENU | B_G1_V2 | X | B_G2_V2 | X | B_G3_V2 | B_ENTER | B_G4_V2 |

| 1 | B_SOFT1 | B_G1_V3 | B_SOFT2 | B_G2_V3 | B_SOFT3 | B_G3_V3 | B_SOFT4 | B_G4_V3 | ||

| 2 | B_SOFT5 | B_G1_V4 | B_SOFT6 | B_G2_V4 | B_SOFT7 | B_G3_V4 | B_SOFT8 | B_G4_V4 | ||

| 3 | B_MARKST | B_G1_V5 | B_MOVEUP | B_G2_V5 | B_MARKEND | B_G3_V5 | B_MOVEDN | B_G4_V5 | ||

| 4 | X | B_G1_V1 | X | B_G2_V1 | X | B_G3_V1 | X | B_G4_V1 | ||

| 5 | X | B_G1_DAC | X | B_G2_DAC | X | B_G3_DAC | X | B_G4_DAC | ||

| 6 | B_SELO1 | B_OUT | B_SELO2 | B_ALG | B_SELO3 | B_DACEN | B_SELO4 | B_KON | ||

| 7 | X | X | X | X | EB_OP1LVL | EB_OP2LVL | EB_OP3LVL | EB_OP4LVL | ||

| U15 | 3 | 0 | X | B_G1_V6 | X | B_G2_V6 | X | B_G3_V6 | X | B_G4_V6 |

| 1 | X | B_G1_OPN2 | X | B_G2_OPN2 | X | B_G3_OPN2 | X | B_G4_OPN2 | ||

| 2 | X | B_G1_S1 | X | B_G2_S1 | X | B_G3_S1 | X | B_G4_S1 | ||

| 3 | X | B_G1_S2 | X | B_G2_S2 | X | B_G3_S2 | X | B_G4_S2 | ||

| 4 | X | B_G1_S3 | X | B_G2_S3 | X | B_G3_S3 | X | B_G4_S3 | ||

| 5 | X | B_G1_NOISE | X | B_G2_NOISE | X | B_G3_NOISE | X | B_G4_NOISE | ||

| 6 | B_NSTYPE | B_NSFREQ | B_EG | B_LFO | B_DACOVR | B_UGLY | B_FAST | B_CH3MODE | ||

| 7 | X | X | B_KSR | B_SSGON | B_SSGINIT | B_SSGTGL | B_SSGHOLD | B_LFOAM | ||

| U16 | 4 | 0 | CSMFREQ ENCODER A | |||||||

| 1 | CSMFREQ ENCODER B | |||||||||

| 2 | RELRATE ENCODER A | |||||||||

| 3 | RELRATE ENCODER B | |||||||||

| 4 | PSGFREQ ENCODER A | |||||||||

| 5 | PSGFREQ ENCODER B | |||||||||

| 6 | PSGVOL ENCODER A | |||||||||

| 7 | PSGVOL ENCODER B | |||||||||

| U17 | 5 | 0 | DEC2R ENCODER B | |||||||

| 1 | DEC2R ENCODER A | |||||||||

| 2 | DECLVL ENCODER B | |||||||||

| 3 | DECLVL ENCODER A | |||||||||

| 4 | DEC1R ENCODER B | |||||||||

| 5 | DEC1R ENCODER A | |||||||||

| 6 | FREQ ENCODER B | |||||||||

| 7 | FREQ ENCODER A | |||||||||

| U18 | 6 | 0 | ATTACK ENCODER B | |||||||

| 1 | ATTACK ENCODER A | |||||||||

| 2 | DETUNE ENCODER B | |||||||||

| 3 | DETUNE ENCODER A | |||||||||

| 4 | HARM ENCODER B | |||||||||

| 5 | HARM ENCODER A | |||||||||

| 6 | OCTAVE ENCODER B | |||||||||

| 7 | OCTAVE ENCODER A | |||||||||

| U19 | 7 | 0 | OP2LVL ENCODER B | |||||||

| 1 | OP2LVL ENCODER A | |||||||||

| 2 | OP3LVL ENCODER B | |||||||||

| 3 | OP3LVL ENCODER A | |||||||||

| 4 | OP1LVL ENCODER B | |||||||||

| 5 | OP1LVL ENCODER A | |||||||||

| 6 | FEEDBACK ENCODER B | |||||||||

| 7 | FEEDBACK ENCODER A | |||||||||

| U20 | 8 | 0 | DATAWHEEL ENCODER B | |||||||

| 1 | DATAWHEEL ENCODER A | |||||||||

| 2 | X | |||||||||

| 3 | X | |||||||||

| 4 | B_CTRL | B_CMDDN | B_CMDUP | B_STATEDN | B_TIME | B_CMDS | B_STATEUP | B_STATE | ||

| 5 | B_LOAD | B_CROP | B_SAVE | B_CAPTURE | B_NEW | B_DUPL | B_DELETE | B_PASTE | ||

| 6 | B_GROUP | B_MUTE | B_RESTART | B_SOLO | B_PLAY | B_RELEASE | B_RESET | B_PNLOVR | ||

| 7 | B_PROG | EB_DATAWHL | B_VGM | B_SYSTEM | B_MDLTR | B_VOICE | B_SAMPLE | B_CHAN | ||

3D Printed Items

The buttons on MBQG_FP consist simply of a 5mm tact switch and up to 2 3mm LEDs on the front panel board, and a 3D printed, transparent plastic button cap which sits loosely on top. It is held in by the front panel, its flanges, and the button and LEDs underneath.

MBQG_FP also uses a number of LED pipes, which are 3D printed, transparent pieces which are held in the slots of the aluminum front panel by friction, and which are intended to cause the slot to light up uniformly when lit underneath by an LED. The original version used LED pipes for all the LED rings, but since this was extremely tedious, I recommend only using the LED pipes for the FM Widget and the DAC VU meter.

Things You Should Know If Having These Printed

- You need 115 buttons and 26 LED pipes, assuming you're not using LED pipes for all the LED rings. However, especially if the 3D printer (machine and/or person) is inexperienced, you will need lots of extras. For the LED pipes, because they are friction-fit, buy at least double the number you will need; and for the buttons, at least 20 extra or so.

- The total cost to have these items printed should be roughly $20-$30 plus shipping. If someone is trying to charge you more than that, either there's an issue (like they got the scale wrong and think you want giant-sized parts), or they're trying to gyp you. If you try to get these printed by a commercial service (e.g. Ponoko), they will charge a minimum of $1 per part and the result will be prohibitively expensive! Have them printed by a real person instead, either a friend with a 3D printer or possibly someone from the RepRap forums.

Things You Need to Tell the Person Printing Them

- The scale in the STL files is 1 INCH, not 1 mm. The buttons should be about 1/2“ or 12mm wide. (This is not intended as an engineering dimension, just as a sanity check–use the actual dimensions in the file.)

- Update: Smithy has added additional STL files in metric scale below.

- Either ABS or PLA transparent filament should work. I had the guy who made them for me do tests with both, and I liked the light-up appearance of the ABS better but the “off” appearance of the PLA better. But they were pretty similar.

- I had the guy who made them for me do tests with different fill rates, and if I remember correctly around 10% fill worked best. 100% fill would be needlessly expensive and would dim the LEDs.

- The buttons need to be printed with the flanges and the cutout down, and the beveled rectangular surface up. The LED pipes need to be printed with the flat surface down and the crown-shaped end up.

Downloads

(You must be logged in with your MIDIbox Forum account to access the downloads)

Additional files provided by Smithy:

Buttons in metric scale for 2mm Front Panel

LED pipes in metric scale for 2mm Front Panel

Assembly Guide

Once you have your front panel PCB, your aluminum front panel, and all the other parts, here's some tips for the assembly process.

- Begin by soldering all the SMD shift registers and resistor packs. The pads aren't very big (if I had known, I would have made them bigger…), and I had a lot of issues with bad connections because a leg which looked soldered wasn't actually attached. If you have access to solder paste and a heat gun, use that. If not, apply solder to two corner pads on the board, place the chip on and melt those two legs into the solder to connect them. Adjust the position so that all the pins line up correctly. Then solder the rest of the legs, making sure to press down firmly with the iron on each leg just before applying the solder, in hopes that the leg will conduct heat to the copper and then when you apply the solder it will flow across the two.

- Solder the diodes, the two discrete resistors, the through-hole resistor packs, and the ceramic capacitors.

- Solder all the tactile switches. Only solder two pins of each switch to start, and make absolutely sure every single button is seated fully before soldering the remaining two pins. If the switch isn't seated fully, the 3D printed button will bind and it may prevent the front panel from going together well.

- Solder all the LEDs which are under buttons or LED pipes. Make sure each is also fully seated, and ideally, pointing as close to straight up as possible. Again, the panel won't go together right if any are sticking out, and buttons may bind if the LEDs under them are a little tilted.

- For each region of LEDs which stick through the front panel: Insert the LEDs into the board. Stick a couple screws in the area up through from under the board (backwards). Drop a 1/4” nylon standoff/spacer and a thin washer on top of each, and then slide the front panel down onto the screws. Secure them with a nut. Now flip over the assembly and drop/push each LED into the hole in the aluminum. Hold up the assembly and make sure all the LEDs are pushed in uniformly. Solder the LEDs.

- For the above step, if these are LEDs around an encoder, instead of securing the front panel with screws while soldering, solder in the encoder before you begin the process, and then use the encoder (with its nut) to hold the front panel to the aluminum while pushing in and soldering the LEDs. Make sure of course that the encoder is seated fully! If the encoder's mounting tabs have trouble going through the mounting holes, bend them a bit with pliers–they will eventually fit smoothly. Make sure to use plenty of solder (and plenty of heat) on the mounting tabs.

- For the LED displays, do a similar process to with the LEDs to ensure they fit correctly in the front panel and are flush with its surface. I used a small piece of wood to hold the displays flush with the surface while soldering them–“pushed in all the way” will not be flush with the surface, it will be below the surface.

- Make sure to mount the electrolytic capacitors behind the front panel, i.e. on the opposite side from all the other components.

Final Assembly

Once you have finished the board and tested it on its own, it's time to put it all together.

- Insert all the LED pipes in the aluminum. May take elbow grease as the aluminum “cuts” plastic off the sides of them to fit.

- Insert long (~5cm) M3 or 4-40 screws through all the holes in the aluminum, in the correct direction. Sit the front panel on your table with the screws sticking up (back side up).

- Lay all the 3D printed buttons in the appropriate cutouts, making sure to get the LED cutout pointing in the correct direction.

- Add a thin flat washer and a 1/4“ nylon standoff/spacer to each screw.

- Slip the front panel PCB down over all the screws. The encoders will hold it up against the table through the holes.

- Loosely cap each screw with a nut.

- Pick up the aluminum so that the front panel PCB slips down into all the holes. Press the PCB where necessary and ensure that the LEDs are in their holes and everything is tightly together.

- Loosely tighten all the nuts.

- For each screw, loosen and remove the nut, then take another screw and put its tip against the tip of the screw sticking through the assembly. Slide the two screws down through the assembly, so that you have now exchanged the original long screw pointing correctly with a screw pointing backwards (out the front of the panel). Then, take your screw of final length, push it against the tip of the backwards screw, and slide them through, so the screw of final length is in its final position. Add a small lockwasher and the nut, and tighten. The purpose of this is to exchange the long screw for a shorter screw without risking the washer and spacer getting dislodged.

- Make sure none of the nuts you use are big enough that they touch any of the soldered connections, especially the ones in the middle of the voice selection buttons.

- Once all the screws are in place, flip over the panel and add the washer and nut to each encoder.

- Finally, hand-tighten all the screws between the screw head in front and the nut in back.