This is an old revision of the document!

Table of Contents

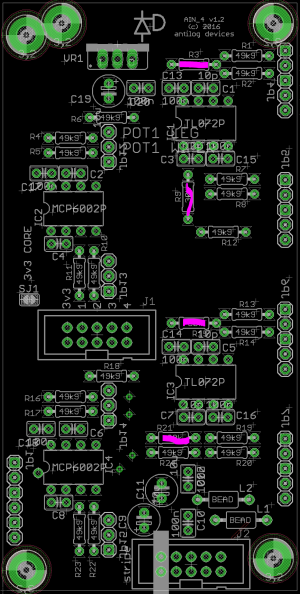

PAD_4*4 module

A neat way to couple WS2812B programmable LEDs (pLEDs) with a silicone button pad (e.g. Sparkfun)

Schematic

Power input is +5V via a 3-pin 100mil connector (or Molex) and a Schottky diode. The value of electrolytic capacitor C1 is not critical.

The pLED chain enters via J2:pin 6 and resistor R1. The resistor should be replaced with a wire link for each additional module (i.e. only the first in the chain gets a resistor, the remainder stuffed with wire links). The serial chain then follows a snake pattern to J3, where additional pLED modules may be connected. The RC (R2, C18) end termination shouldn't be necessary, but can be trialled should problems with signal reflection arise.

Switches are connected in a 4*4 matrix with the given mapping. D0 refers to pin 10 of the IDC header (i.e. top right) for both DIN and DOUT.

BOM v1.2

| Type | Qty | Value | Package | Parts | Notes |

|---|---|---|---|---|---|

| resistors | |||||

| 1 | 220-470R | 0204/7 | R1 | replace with wire link for each additional module | |

| capacitors | |||||

| 16 | 100n | 1206 | C2-17 | ||

| 1 | 100-1000u | electrolytic 3,5-6 | C1 | ||

| diodes | |||||

| 1 | 1N5187 | DO41-7.6 | D1 | ||

| 16 | 1N4148 | DO41-7.6 | remaining axial diodes | ||

| 16 | WS2812B | 5mm | programmable LEDs | ||

| headers | |||||

| 4 | 2*5 (shrouded) SMT | J2-5 | |||

| 1 | 1X03_SMALL | J1 | can use Molex 22-23-2031 | ||

| switches | |||||

| 1 | Sparkfun 4×4 pad | ||||

| misc | |||||

| 1 | acrylic bezel |

Versions

v1.1: current release. Some traces moved around, grounding error fixed. J1 power header changed to offset pads so an SMT header may be soldered if desired.

v1.0: errata: J4 and J5 have no connection to ground. J1-3 do carry ground, so it isn't a problem if the DIN/DOUT modules share the same power rail.

Assembly

In order to keep the button pad flat, it's best to solder all components on the rear of the board i.e. opposite the pads. The contacts are exposed ENIG, so try not to damage the surface by scratching or splashing solder/flux on them.

Start by tinning one pad (preferably not the pad joined to the ground plane with thermals) of each 1206 capacitor, making a “tack” joint, aligning the part and cleaning up if needed.

The best way to fix the 1N4148 diodes is to place the parts then solder from the same side only the anode lead on the inside of the button pad. Turn the board around and clip the cathode lead as close to the board as possible. You can even pull the lead out slightly. On the rear of the board, solder the cathode with as little solder as possible. The aim is to leave no solder bump on the frontside. Try to give equal care to the other through hole components (R1, C1, D1, J1).

If using shrouded headers, ensure the notch points on the same side as the pin 1 designator.

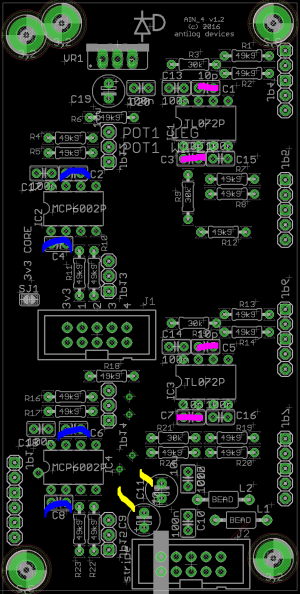

Resistors

- four 30k resistors marked in pink

- remainder are 49k9

- for best results, match R1/R2, R7/R8 (and so on), and R4/R5/R6, R10/R11/R12 (and so on).

- the value is less important than the minimum deviation.

Capacitors

- four 10p as marked in pink

- electrolytics in yellow

- blue are optional (i.e. probably unnecessary)

- remainder are 100n.

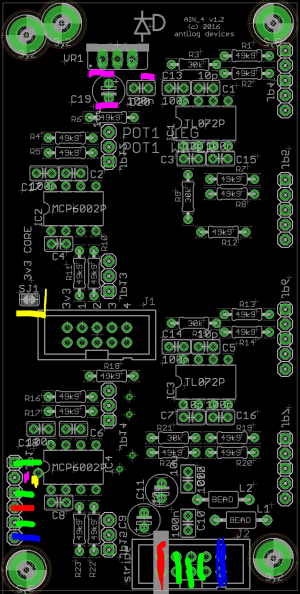

Power

- J2 is a standard Eurorack header

- red = -12V

- blue = +12V

- green = 0V(ground)

- for Core power, bridge the solder jumper marked in yellow

- otherwise install the Vreg circuit in pink

- IMPORTANT only choose one of these 3v3 power options! Don't install the regulator if the solder jumper is bridged.

Headers

For connection to a Control Board, use pin headers placed on the opposite side as the rest of the components i.e. follow the silkscreen markings. For standalone use, you probably want header pins (or sockets, or even bare wires if you wish) on the same side as the remaining circuitry.

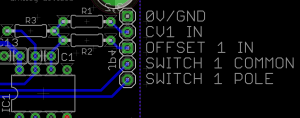

Standalone use

For simplest results, use the complementary Control Board. Otherwise see below for header functions.

Five pin header

- IN = CV input

- for scaling bipolar CVs, connect or switch into OFFSET (e.g. +5V; n.b. the offset should be referenced to the common 0V)

- for 0-5V operation, leave SWITCH open; for 0-10V operation, jumper or switch in COMMON to POLE

Three pin header

- with a 100k pot facing you, solder the left leg to 0V(ground)

- centre to WIPER

- right to LEG

- WIPER and LEG may be jumpered if pots aren't desired, but it is quite useful to have an attenuator to trim down variable CVs or even clip the second op amp for crunchy waveforms!

Interconnection to Core

J1 carries the scaled CV to J5A or J5B of an STM32F4 Core module.

License

Currently the design is © 2016 antilog devices with all rights reserved; all documentation is CC BY-NC-SA 3.0.